Stainless steel grades include carbon (less

than 1.2%), iron, chromium (10.5% - 30%), molybdenum, nickel (at least 8 %) and

different alloying elements. It is a famous steel utilized in diverse products,

tools, gadget, and systems that serve in lots of industrial, commercial, and

home applications.

Corrosion resistance is the maximum

treasured belongings of stainless metallic. Chromium is the alloying detail

accountable for corrosion resistance. This detail reacts with oxygen in air and

water and bureaucracy a thin, solid chromium oxide movie shielding the

underlying steel surface. Molybdenum complements corrosion resistance with the

aid of using shielding the movie from pit formation. The shielding layer is

regenerated after moderate abrasions. However, rust can nevertheless be

fashioned while the layer is seriously broken after publicity to chlorides,

sturdy cleansing agents, environments with excessive salinity and excessive

humidity, and after excessive abrasion.

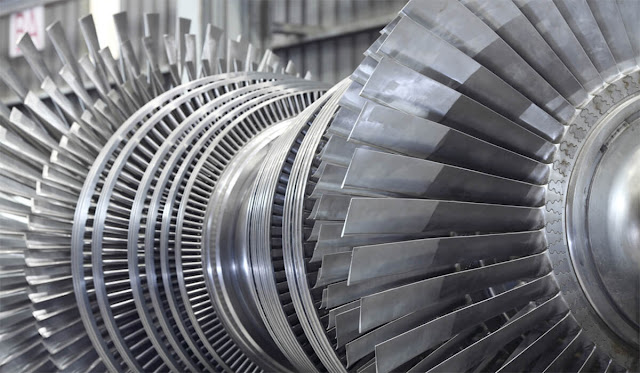

Aside from corrosion resistance,

stainless steels are recognized for his or her outstanding mechanical

residences which include excessive strength, toughness, ductility, fatigue

strength, and put on resistance. Stainless steels can face up to excessive

temperatures, excessive pressures, and cryogenic environments. They are

non-reactive to maximum chemical substances; hence, they're typically utilized

in chemical dealing with gadget and vessels. They additionally have an

aesthetically pleasing, lustrous, and vivid surface.

Types of Stainless Steel Grades

Austenitic

Stainless Steels

Austenitic stainless steel is the maximum not unusual place sort of stainless-steel. It is called after an English metallurgist named Sir William Chandler Roberts-Austen. It is the maximum broadly used class of stainless-steel, which contains the two hundred and three hundred series.

.jpg) |

| Austenitic Stainless Steels |

Ferritic

Stainless Steels

|

| Ferritic Stainless Steels |

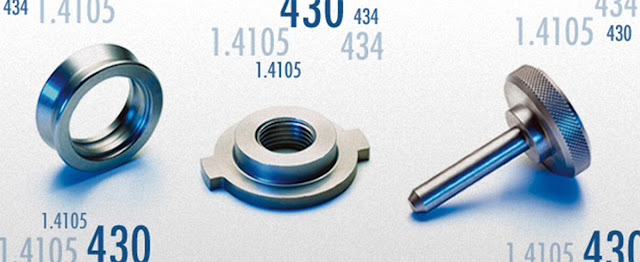

Martensitic

Stainless Steels

Martensitic stainless steel has a tetragonal body-centered crystal structure. They are composed of 11.518% chromium and 0.11.2 µr bon. The relatively high strength and brittleness of martensitic stainless steels is due to their high carbon content. However, martensitic stainless steel contains almost no nickel, so its corrosion resistance is low. Martensitic stainless steels are classified into two types, low carbon (0.050.25 carbon) martensitic steel and high carbon (0.611.50 carbon) martensitic steel, based on their carbon content. Low carbon martensitic steels provide better corrosion resistance, while high carbon martensitic steels have higher strength and are more brittle.

Martensitic stainless steel can be improved by heat treatment processes such as hardening, annealing, quenching and tempering. Martensitic stainless steel is magnetic and impact resistant. However, it is fragile and difficult to weld and mold.

|

| Martensitic Stainless Steels |

Duplex

Stainless Steels

Duplex stainless steel contains approximately equal proportions of both austenite and ferrite phases in its microstructure. They are twice as strong as regular austenitic and ferritic stainless steels. Their toughness, ductility and formability are superior to ferritic steels, but they do not reach the levels of austenitic steels. Duplex stainless steel has excellent resistance to stress corrosion cracking from the ferrite side. Since this property depends on the composition, the corrosion resistance of duplex stainless steels varies greatly. Increasing the content of nickel, molybdenum, and nitrogen increases resistance to pitting and crevice corrosion. In terms of cost, duplex stainless steel continues to be a cheaper alternative to austenitic stainless steel.

|

| Duplex Stainless Steel |

Precipitation-Hardened

Stainless Steels

Precipitation hardening stainless steel (PH steels) contains small amounts of copper, aluminum, titanium, and

molybdenum. After the elements of

stainless steel are alloyed, the stainless steel is aged to precipitate these elements

as hard intermetallic compound elements. The precipitated phase impedes the

movement of dislocations, which is a defect in the crystal lattice structure,

and gives stainless steel excellent strength and hardness. PH stainless steel

has corrosion resistance comparable to that of austenitic stainless steel.

PH stainless

steels are classified into three types: martensitic, austenitic, and

semi-austenitic PH stainless steels. Austenitic PH steel retains its crystal

structure at all temperatures. Semi-austenitic PH steels remain austenitic after

solution heat treatment and quenching. The austenite structure transforms into

martensite after cryogenic or cold

working.

|

| PH Stainless Steel |

0 Comments